Our Buildings at Risk feature covers buildings and structures on our island

Following the last feature on seawalls and groynes, this week Dave Martin of the Isle of Man Natural History and Antiquarian Society looks at breakwaters - structures erected to reduce wave damage to ships in our harbours and anchorages, and sometimes to reduce beach damage as well.

Manx men and women have interacted with or depended on the sea ever since shortly after the last ice age when the land-bridge with Cumbria was inundated by recovering sea levels.

Until aviation in the 20th century, we have been entirely dependent on the sea for access to adjacent islands for trade or military purposes.

Our fishermen have long harvested its bounty and in recent centuries it has become a leisure venue and playground as well.

No part of the island’s coast is immune from the effects of wind, tide or waves.

Tidal streams flow up the Irish Sea from St George’s Channel between Wales and Ireland and out through the North Channel between Scotland and Northern Ireland, and then back again every 12½ hours giving rise to predictable currents (tidal streams) predominantly along the coasts.

These tidal streams can cause longshore-drift erosion and deposition (Buildings at Risk, Isle of Man Examiner, October 20, 2020) but while a hindrance to mariners, unless in a confined area like the Calf Sound, tidal streams only rarely cause damage on their own.

However, any boat that is light enough to float on water is vulnerable to the effect of wind and waves, and prudent mariners try to shelter their craft when possible.

The ’weather’ - wind and waves - can come from all points of the compass.

Wind and waves, if onshore - ie blowing from seaward on to the coast can drive a vessel up the beach or onto rocks; whereas an offshore wind can cause a moored boat to break loose or drag its anchor and disappear seaward.

The wind can cause enough mischief by itself, but it is difficult to erect shelters or windbreaks big enough to protect harbours or anchorages.

Waves are caused by wind blowing over the water, gradually moving the surface layer in the same direction as the wind. It is these waves that can cause significant damage, as TE Brown said ’Rolling in, rolling in, rolling in upon the dead lee shore’.

It is though possible to take steps to reduce the waves’ power and hence the damage they can cause.

Even a strong wind, if it only covers a short distance such as across a reservoir, won’t whip-up waves of any size.

At the other extreme in mid-ocean, with no obstacles to wind or the building waves for hundreds of miles, fearsome swells many tens of feet high can build.

The distance that a wave can build without obstacle is so important that mariners have a special term for it - the ’fetch’. A short fetch = limited opportunity for waves to build, whereas a long fetch with a steady wind equals bigger waves.

In early days, and even now, if a boat is small and light enough, shore-launched boats can be dragged clear of the water when not in use - up a beach, or on the bank of a river.

As the size of number of ships grew, harbours grew up on the banks of rivers and creeks.

These eventually provided quays to which ships could moor to work cargo, and by virtue of being slightly inland, provided some shelter from wind and were less vulnerable to wave action unless the waves were rolling into the mouth of the harbour - or you had a natural obstacle such as the Isle of Wight which protects the Solent ports by reducing the fetch.

However, man went on to try and construct barriers to reduce the impact of onshore waves - breakwaters.

There are relatively few structures whose name so completely captures their purpose and working as a breakwater.

A breakwater works by causing the waves to break before they reach the shore/anchorage/harbour, so dissipating much of their energy - similar to the way the barriers outside a school’s roadside gates slow children down before they spill onto the roadway.

Early breakwaters just consisted of piling rocks on a beach when the tide was out, or more usually dropping them on the seabed and hoping they didn’t roll too far when dropped. These stone banks didn’t stop the waves, but - continuing the highway analogy - did slow some waves, a bit like passing over a ’sleeping policemen’ in the carriageway.

Construction and maintenance of these coastal stone defences was organised in a similar way to maintenance of the roads.

On land, farmers and landowners had to supply manpower and carts for a certain number of days each to maintain roads in their parish. In 1630, every fishing boat in Ramsey Bay was ordered to contribute two boat-loads of stones annually to replenish a barrier off the mouth of the Sulby River, known locally as ’The Ramsey Fence’.

In 1660, the ’Douglas Bulwark’ was repaired by the local militia.

Over time, local stone banks and walls - all that could be done by local resources - were constructed and washed away again and again.

The want of protection from the waves’ onslaught led, for example, in 1787 to the loss of 84 yards of the pier in Douglas, complete with the light on the end of it, and this contributed to that year’s herring fleet tragedy in Douglas bay.

After Revestment, the 4th Duke of Atholl managed to get the English government to appoint a commission to look into the state of the island, and they received plans, including one for a great breakwater from Douglas Head to the Conister Rock and thence to the shore.

In the early 1800s, breakwaters were built in a number of English ports, usually by depositing banks of more and bigger, but un-bonded, rocks.

For example, in 1812, four million tons of rock were used to build Plymouth breakwater which spans much of, and protects, Plymouth Sound from the English Channel.

In 1864 the first engineered breakwater was built at Douglas.

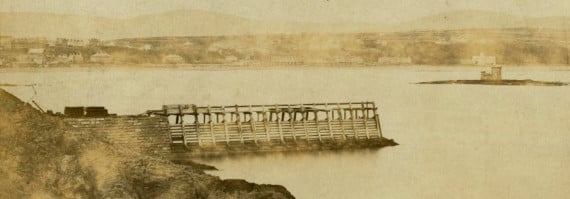

Rather than all masonry, it was built on the Abernethy principle with a framework of wooden piles driven into the seabed, joined by rails which gave rise to the nickname Abernethy’s birdcage, then in-filled with random stone.

Possibly because of poor or ill-supervised construction (Mr Abernethy had projects all around Scotland, Wales, the Isle of Man, Falmouth, even as far as South Africa) Douglas’s Abernethy breakwater lasted barely a year before it was swept away. Those at Ramsey and Peel fared better though.

The skeletal nature, especially at upper levels, of an Abernethy breakwater was no real impediment to its function as a breakwater - a breakwater can be porous and doesn’t need to keep the tide out (like a sea wall). The wooden framework allowed access for maintenance and the usual beacon or lighthouse at the end.

It was soon found that the timber, however good, was decaying, especially where repeatedly covered and uncovered by successive tides.

This destabilised the un- or poorly-bonded stone core, so the Abernethy birdcages were clad in protective masonry.

When a trench was being excavated to lay the pipeline along Peel breakwater to carry fuel oil to Peel power station, Abernethy’s timbers were revealed still in-situ.

Once clad in masonry and fully decked, the Abernethy breakwaters were increasingly used as jetties or piers where vessels could moor alongside to load or discharge cargo, fish and passengers, without having to go into the harbour.

Many were still though known as breakwaters, such as at Peel.

In Europe, breakwaters were more usually known as Moles, and many Manx folk will have heard of the Eastern Mole at Dunkirk - really just a breakwater built to shelter the harbour, but also providing a narrow walkway from which Steam Packet vessels heroically evacuated many of the British Expeditionary Force in Operation Dynamo in 1940.

MASONRY BREAKWATERS

Whilst the Abernethy method was popular, other methods were used depending on local geology and conditions.

At Derbyhaven, at one time there were plans to build a Plymouth Sound style breakwater enclosing the whole bay from Fort Island to Ronaldsway Point, with a small gap for ships to enter and leave - this plan was supported by, among others, Captain John Quilliam.

Eventually though a smaller breakwater was constructed in 1842 further into Derbyhaven Bay, built on the solid foundations of the North Rock

Port Erin bay is exposed to a real long fetch when wind and waves come up St George’s Channel, potentially all the way from the Western Approaches.

Events at Douglas had proven the vulnerability of an Abernethy birdcage, so when it came to a breakwater at Port Erin, it was decided to try a more substantial work using massive rocks quarried immediately opposite the root of the breakwater.

These quarries formed the plateaux used to build the most recent marine biological station.

Construction began in 1864. Money ran out 1868 when only 500 feet had been built, eventually finished in 1876, but in 1881 a storm swept away the head (seaward end) of the breakwater and light, 1884 breakwater destroyed.

The rectangular concrete blocks used atop the rocks were no match for the sea’s power - the smooth-sided blocks were pushed aside despite their weight.

In parallel with and to facilitate increases in the size of stone, rock and then concrete used for breakwaters there was also increasing use of mechanisation, including the first steam railway locomotives on the island.

Abernethy birdcages could be filled with stone transported on hand- or horse-pulled tramways, or with a small steam engine.

At Peel, stone was transported from quarries on the headland by tramway and then to the breakwater by a small De Winton locomotive whose vertical boiler gave them a generic nickname ’coffee pot’ but which was known locally as the Moddey Dhoo.

At Port Erin where massive rocks were being moved, an equally massive engine was brought from Plymouth harbour.

In the last century, machinery grew, and we saw the ingenious self-interlocking ’stabits’ used to form the extension of Douglas breakwater beyond the Battery Pier.

The picture isn’t all positive though.

In recent years, Derbyhaven breakwater has been neglected and instead of a modest pointing job, there are now plans to drill some 4,000 holes into the blocks to anchor steel reinforcing mesh and then entomb the carefully-crafted stone blocks in a ’concrete overcoat’.

Comments

This article has no comments yet. Be the first to leave a comment.