Dave Martin continues our series looking at buildings lost, saved, and at risk. This week he looks at a once wide-spread industry on the Isle of Man - the processing of flax - of which remarkably little remains overtly visible.

Wool was not the only fibre spun and woven on the island.

At one time probably as much flax was processed and woven as wool.

Flax and hemp are field-grown crops which, unlike wool or cotton, have relatively long and straight fibres which make them easier to align and produce yarn.

The coarse fibres of hemp when spun into yarn could be woven into sacking, but were typically used to make cordage which was woven into nets, or twisted-up in ropeworks to make hempen ropes.

Even though nets and ropes were made on the Isle of Man, there was relatively little hemp production, compared to the volume of flax that was grown and processed.

Flax has finer fibres which produce a finer yarn; the longer fibres also mean a stronger cloth typically results. When woven from the finer yarn, the cloth is known as linen; when thin yarns are combined (twisted) and woven, strong canvas is produced.

Linen has been woven for millennia, and can produce light but strong fabric.

Warriors’ shields are known to have been faced with leather to armour them. But it has been suggested that, from Roman times, linen was used on some shields - bonded on with paint or varnish, possibly like laminating with glass-fibre mat or kevlar.

Preparing the yarn

The journey from field to fabric can be split into two stages - growing and processing the flax into yarn and weaving.

Whilst water is needed for processing flax, it doesn’t grow well ’with wet feet’, so it was often grown near water.

Flax was usually harvested when sufficiently grown to produce the best fibres, though sometimes it was left to mature and the seeds collected either for sowing the next year or for processing as linseed.

Some types of crop are sown once and then cut and harvested year after year, but flax takes a lot out of the soil, so it was normally sown on fresh ground each year.

As there was no need to leave the rootstock in place, to maximise the yield it was often pulled rather than cut.

Once the flax straw had been collected, it was ’retted’ to loosen the various components so they could be separated.

Just laying the flax out in a field will achieve that eventually, but it was usual to submerge bundles of flax under water to hasten their breakdown. Sometimes this was done by weighting bundles down in a stream or river, but often convenient still-water was used - a ’retting pond’ or as they were known on the island, a ’flax dub’.

When retted-down, the flax was beaten or scutched to separate the wanted fibres from both the woody and soft pith material. This could be done by hand, pounding with sticks, flails or logs; but in later days scutch mills sprang up alongside sources of water power.

Once all loosened and beaten the flax was ’heckled’ or combed to separate it and align the fibres prior to spinning; this was very similar to carding wool or cotton, but the nature of the flax meant the initial heckling used a long-toothed comb.

Spinning, like for wool, was long a domestic side-line; it could be spun using the same spinning wheel, although it was sometimes found the dried flax fibres had to be dampened as they were being spun.

Weaving

Weaving linen from flaxen yarn is not that different to weaving with wool, the only significant difference is that the yarn might be thinner and hence more threads to the inch.

Some weavers wove flax, cotton and wool. Others specialised. Flax can produce a spectrum of fabric - from fine linen to coarse canvas; most home- and small-scale flax weaving was for linen.

Wool fibres are naturally ’wavy’ with many bends along the length of each fibre on the sheep’s back (known as ’the crimp’) and when spun into yarn and then woven or knitted, this residual waviness means air is trapped and the resultant garment has insulating properties.

In comparison, when linen is woven from flax, the lack of ’crimp’ means the fibres, as they lie close together, have minimal air trapped between them, so the resultant linen doesn’t have the same insulating properties as woollen material.

Linen was used for cooler-wear and for items such as tablecloths; and because of the fine and stable weave, became popular as ’a blank canvas’ for artists and embroiderers.

Mixed wool/linen weaving, known as ’linsey-woolsey’, is also recorded for such as ’health belts’; it was claimed that flax had health benefits, but it may just have been the linen gave dimensional stability and the wool gave warmth.

Raw linen has a warm grey / light beige colour, but could be bleached and then dyed, sometimes in the yarn but also ’in the piece’ after weaving - be that fine linen for an undershirt or tea-towel, or canvas for ’red sails in the sunset’.

Unbleached linen is sometimes described as ’ecru’ (French for raw or un-bleached).

Flax on Mann

Flax has certainly been processed on the Isle of Man for at least a significant part of the last millennia, reaching its peak in late 19th century. It became a cultivated crop on the Isle of Man, albeit never on the industrial scale which arose in Ulster in the 19th century.

Basil Quayle’s 1794 survey of Manx agriculture reported: ’The growth and manufacture of flax is very general throughout the whole island, almost every farmer and cottager growing a little, both for the use of their families and exportation.’

There are certainly records of ’flax mills’ but in the same way that woollen mills could provide a range of services, there’s no way of knowing if a ’flax mill’ was just scutching and heckling, or spinning, or weaving, or bleaching and dying - or a combination of these.

Flax mills abounded on many of the streams where power was found, in locations such as Glen Auldyn and Glen Roy. In the same way that corn and woollen mills may have used the same waterwheel, it is possible that not all flax mills were used solely to process flax.

Some also evolved, such as the Silverburn/Ballasalla mill - originally developed in 1767 as a fulling mill for processing flax by John Quayle, and later owned by George Quayle of Bridge House in Castletown (who shipped linen to America). The building was converted first for grinding ochre, and later into a dwelling ’Grey Tower’ in 1901 - an example that shows new uses can provide new lives for a building.

Similarly, the Ballasalla ’Factory’ had several lives - as Delapryme’s cotton mill, as a fishing-net works, then a mill to process flax.

Most rural flax mills were powered by water, but there are suggestions that there was at least one wind-powered flax mill in the North of the island.

Linen wasn’t just woven for domestic consumption, it was also exported. The amount used at-home and sold locally cannot be determined, but the Receiver General’s returns show that between 1781 and 1810, average exports of linen were 40,000 to 60,000 yards of linen fabric each year.

Tromode

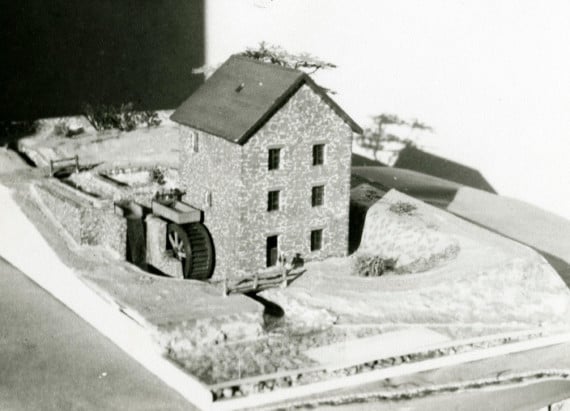

The pinnacle of the Manx flax industry was Moore’s Tromode Flax-Spinning, Bleaching, and Sailcloth Manufactory.

Moores started by Douglas harbour, then moved to Factory Lane (now Wellington Street). The Tromode works were established in 1814 by Edward Moore, who was succeeded in 1823 by his brother James and James’s son William Fine Moore.

The works were powered by water, with sophisticated water management feeding a waterwheel then later a turbine; augmented by steam engine when there was insufficient water to drive the wheel/turbine. They also had their own plant to manufacture gas for lighting.

Moores did use some Manx flax but increasingly imported flax from the Baltic and Northern Ireland, from whence they also brought in weavers. The workforce reached some 150 in number.

To accommodate the workforce close at hand, and build loyalty, WF Moore built the island’s only industrial village: Cronkbourne village - houses, a school and chapel - for their workers.

Archibald Knox was born in one of the houses, his Scottish father was employed as a master machine maker at the Tromode works.

In 1882, a water-powered Crompton dynamo was installed, this supplied not only the works, but also a small number of lights in Cronkbourne village.

Moore’s canvas stamped with the Three Legs was exported world-wide to navies and for merchant fleets.

Supplying Moore’s Three Legs canvas to Isambard Kingdom Brunel’s ’Great Britain’ was one of their greatest coups, but also an omen.

Following loss of a contract to supply much of the British Admiralty’s sailcloth, as steam took over, the works eventually closed in 1906. The Three Legs brand was sold to a rival in Crewkerne and the sailcloth works was eventually re-used as a laundry for the burgeoning visiting trade.

What remains now?

For an industry that spanned every parish, very little physical evidence remains, but there are some documentary sources.

The Folk Life Survey in the Manx Museum Library has many recollections of growing, spinning and weaving flax. Recorded mid-twentieth century, these recall life in the later 19th and early 20th century.

Going back further, documents such as the Letter books from the Bridge House papers, and Deeds relating to various mills, provide an insight back to at least the 1700s into their ownership and value. There are also more poignant glimpses such as that relating to James Sampson, who was buried at Kirk Michael on October 25 1769 Killed by the log-wheel of the Flax Mill.

Retting ponds or flax dubs were probably the most prolific structures used for flax processing, but there was nothing specific or distinctive about them - even if some were specifically constructed for flax retting, nowadays any that do remain are ’just another dub or pond’.

Whilst an engine house and vestiges of an early stone flue remain at Tromode, there is very little elsewhere which is known to be definitely connected with the actual processing of flax. The only significant built heritage from the flax industry is Cronkbourne Village, whose future is uncertain.

Correction: in the previous Buildings at Risk of November 19, the photograph of the generating plant at Tynwald Mills was captioned that it was driven by a steam engine. A reader has queried that, and it has been discovered that the generating plant pictured at Tynwald Mills was powered by a Crossley gas engine.

.jpeg?width=209&height=140&crop=209:145,smart&quality=75)

.jpg?width=209&height=140&crop=209:145,smart&quality=75)

Comments

This article has no comments yet. Be the first to leave a comment.